- Meehanite Class FC30 casting with slide way provides high stiffness and wear resistance maintaining the accuracy of the machine.

- Spindle lateral design creates stability during heavy cutting.

- Vertical feeding uses 2 high stiffness and rigidity linear roller guides,

- 45CA(Blocksx6)/HR-800AND,65CA(Blocksx6)/HR-1000/1200AND allowing smoothly vertical feeding whilst maintaining high stiffness.

- Small workpiece suction is accomplished by fine electrical magnetic chuck.

- Home

- Products

- Rotary Surface Grinder

- Vertical Rotary Surface Grinder VR-1000AND

Vertical Rotary Surface Grinder VR-1000AND

-

-

DESCRIPTION UNIT VR-1000AND Rotary magnetic chuck dia. mm 1000 Maxi grinding radius mm 500 Distance of table surface to spindle surface center mm 400 Rotary magnetic chuck speed r.p.m. 5~20 Rotary magnetic chuck horse power kw 7 Spindle motor HP 50 Spindle speed (50/60Hz) r.p.m. 870/1175 Auto downfeed horse power kw 1.5 Vertical hand wheel downfeed per revolution MPG/mm x1, x5, x10 /

0.1, 0.5, 1Vertical hand wheel downfeed per graduation MPG/mm x1, x5, x10 /

0.001, 0.005, 0.01Wheel size (dia x width x bore) mm 150x50x25x8 Net weight / gross weight (approx) kg 13000/14000 Packing size (LxWxH) mm 5100x2950x3200 -

Coolant system Magnetic filter Auto. paper strip filter with magnetic separator and coolant system Oil mist collector

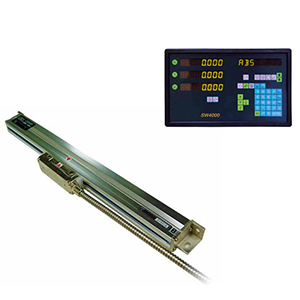

Demagnetize On line wheel balance system (Manual) SBS (Auto) Digital readout

Inverter Air-Conditioner -

- Precision bearings

- Hydraulic components

- Precision knife

- Automotive components

- Other Precision pars